How to walk on a roof safely guide

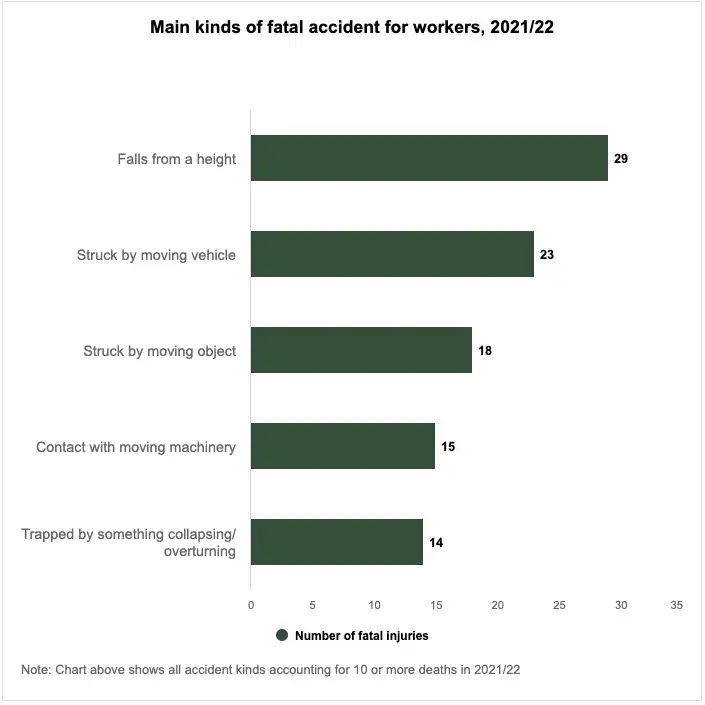

Roof safety is an important concern in the UK, as falls from height are a leading cause of accidents in the construction industry. According to the Health and Safety Executive (HSE), falls from height accounted for 29% of all work-related fatalities in 2020/2021. Roofs can be hazardous environments due to the potential for unstable or fragile surfaces, electrical hazards, and the apparent risk of falling. Employers need to implement appropriate measures to ensure the safety of workers when working on roofs.

Employers and workers must take proper precautions when working on roofs to prevent accidents and ensure their safety. This guide will discuss the importance of roof safety and provide tips and best practices for working on roofs safely. Following the guidelines and best practices outlined in this guide can help reduce the risk of accidents and injuries while working on roofs and ensure a safe and productive work environment.

Before accessing the roof

Before accessing the roof, consider these things variables:

- Can the work be completed from the ground?

- Can the work be carried out using any other way methods?

- Is there specialised equipment that can perform the task?

If the work does require personnel to go up to the roof, it is crucial to conduct a risk assessment, wear appropriate clothing and evaluate the weather.

Risk assessment

A risk assessment is a method of recognising, evaluating, and prioritising potential hazards and risks that may be presented in the workplace. This includes any risks that may be present when working on a roof.

In the UK, employers have a legal obligation to assess their workers’ health and safety risks and take appropriate measures to control them. This includes conducting a risk assessment when working on a roof. Failure to properly assess and manage risks can result in accidents, injuries, and legal liability for the employer.

Some common hazards that may be present when working on a roof include the following:

- Slippery or unstable surfaces

- Height-related risks, such as falls from height

- Electrical hazards, such as overhead power lines or electrical equipment on the roof

- Weather-related risks, such as strong winds or lightning

- Structural hazards, such as weak or unstable roofs or walls

Clothing

employers must provide their workers with personal protective equipment (PPE) when they go up to roofs. This includes hard hats, safety glasses, gloves, and Hi-Vis clothing. The appropriate clothing can help to protect workers from the hazards that may be present on a roof. This includes risks such as falls from heights, electrical hazards, and weather-related risks such as strong winds or extreme temperatures. In addition to protecting workers from hazards, choosing suitable clothing can help maintain comfort and productivity.

Weather

Inclement weather can present a range of hazards, including strong winds, lightning, extreme temperatures, and slippery surfaces. Before beginning work on a roof, check the weather forecast, and take steps to minimise the risks associated with adverse weather conditions. As noted in The Work at Height Regulations 2005, the weather and wind must be considered when planning to access a roof. A sudden blast of wind can cause a loss of balance. Do not access a roof in windy weather. Workers can effortlessly be thrown off while carrying out a task on a top, particularly when handling large equipment on the roofs of industrial buildings.

Follow the advice of the UK Met Office, which provides regular updates on the weather forecast and any severe weather warnings that may be in effect.

Accessing the roof

When accessing the roof, use the appropriate equipment and have supervision. This may include ladders, scaffolding, or other means of access, as well as fall protection equipment such as harnesses. The point of access should also be carefully considered, as accessing the roof from an unstable or unsafe location can increase the risk of accidents.

Point of access

Accessing a roof requires the right point of access. The correct access point allows for safe and efficient movement on the roof, which can keep your team safe. Using the right access point can also help to protect the roof itself. Climbing on the roof or using the wrong access point can damage the roofing material or structure, leading to costly repairs and potentially compromising the safety of the building.

Hatches and doors should be inspected to ensure that they are safe for workers. This includes checking for any damage or wear that could compromise the stability or integrity of the access point, as well as ensuring that it is properly secured and in good working condition. It is crucial to notify site managers and management if any issues are recognised during the inspection process. They may need to repair or replace the access point and install additional safety measures. By regularly inspecting and maintaining the point of access to the roof, employers can help assure their workers’ safety and prevent accidents or injuries.

Equipment for accessing a rooftop

When working on a roof, use proper equipment to ensure the safety of yourself and those around you. This includes wearing a harness and using fall protection systems to prevent falls from heights. Use ladders or scaffolding to access the roof and motorised lifts such as MWEPS.

Permanent roof access equipment, such as ladders or fixed access points, is typically used for buildings requiring frequent or ongoing roof access. These types of equipment generally are more expensive to install but can provide a safe and convenient way for workers to access the roof. Portable roof access equipment, such as ladders or scaffolding, is often used for temporary or infrequent access to the roof. They are generally easier to set up and remove and more cost-effective than permanent equipment. However, they may be sturdier and more reliable than permanent access points.

Motorised roof access equipment, such as lifts or cherry pickers, are used for buildings requiring frequent or ongoing roof access and can be particularly useful for tall or hard-to-reach buildings. These types of equipment are generally more expensive to install and maintain but can provide a fast and efficient way for workers to access the roof. In general, the choice of roof access equipment depends on the precise needs of the building and the frequency of access to the roof.

Supervision

We recommend having supervision. Although it is not a legal requirement, having supervision while working on roofs can prevent fatal accidents for several reasons, such as:

- Roofs can be hazardous environments. Having someone trained in proper roof safety can provide guidance which will help prevent accidents and injuries

- Supervision allows the work to be monitored appropriately, ensuring the accuracy of the work and the safety of the team working on the roof.

Traversing the roof

Walking on a roof can be dangerous. Ensure that the roof surface is stable and in good condition before walking on it, as structural damage or roof type can increase the risk of falls or other accidents. Additionally, workers should be aware of any hazards that may be present on the roof, such as electrical wires, skylights, or other openings, and take steps to avoid these areas.

Walking path

A walking path is a designated route that workers should follow when moving around on a roof. This can help to reduce the risk of falls and other accidents by directing workers away from fragile or unstable surfaces, electrical hazards, and other potential dangers.

For example, on a flat roof, a walking path should be established to avoid areas where the roof is in poor condition or where there are openings, such as skylights or vents. On a pitched roof, a walking path should be used to avoid the slope of the roof and any other hazards, such as tree branches or overhead power lines.

Suppose there are no designated walking paths on the rooftop. We recommend speaking with management and the site manager to make certain that the roof has stable and secure walking places. Also, there should be clear signs around unsafe areas so that the workers know which areas to avoid.

Roof type and edge

Know the roof type. Roofing materials have different characteristics that can affect their stability and durability—footwear matters. Choosing footwear with the proper protection and grip will stop slipping and protect your workers when performing their tasks on a rooftop.

How to walk on a metal roof

Standing seam roofing is usually safe to walk on with some precaution, while metal tile roofing and corrugated panels should be walked on in lower spots closer to the roof decking. Metal shingles should be walked on in the upper half of the panel, and it may be necessary to use foam backers to firm up areas that may receive repeated foot traffic. For trapezoidal roofs, ensure you sidestep between the ridges and have a footing on one foot before lifting the other. Watch this video for a demonstration.

How to walk on a non-metal roof

non-metal membrane-type roofs require a lot of caution as they are usually slippery due to their smooth finish. Be aware that sharp objects can affect the roof’s membrane and cause tears. This can be minimised by only accessing the top when it is dry and wearing adequate foot protection.

Common environmental hazard

There are multiple objects and hazards that can be found on roofs that can cause considerable harm to workers. It is vital to be aware of these risks and avoid them. Some everyday objects and hazards that may be present on a roof include:

- Electrical hazards, such as overhead power lines and electrical equipment on the roof. These hazards can be deadly if workers encounter them. Stay away from them and use appropriate protective equipment, such as rubber gloves and insulating mats.

- Structural hazards, such as weak or unstable roofs. These hazards can pose a risk of falls or collapses, so inspect the roof for signs of damage or instability before beginning work and avoid working on any areas that are not safe.

- Slippery or unstable surfaces, such as wet or icy roofs. These surfaces can be dangerous for workers, especially if they are not wearing non-slip shoes. It is essential to take extra care when walking on slippery surfaces and to use caution when moving around on the roofs.

Object-based hazard

Safety systems such as platforms and stepovers are all vital safety measures that can help improve workers’ safety when working on roofs.

Tasks that require the workers to move to a higher or lower point on the roof can be a cause of incidents. Inform management or the site manager if the rooftop does not have a specified system for accessing the higher or lower points.

These systems can help reduce the risk of severe injury or death in a fall and are especially important when working at heights. Platforms such as stepovers allow workers to access any part of the roof in a safe manner.

Getting off the roof

When getting off the roof, follow the same precautions as when accessing the roof. This includes using appropriate equipment, such as ladders or scaffolding, and having supervision. It is also significant to take care when walking near the roof’s edge, as falls from heights can be perilous. Using the proper safety equipment and following established procedures ensures you can get off the roof without incident. Before you start your dismount from the room, clean the surroundings so that the next person will have a clear view of the area and have fewer trip hazards. Finally, have someone supervise the worker’s dismount of the roof and check that all equipment is securely attached so it doesn’t fall and harm others on the ground.

Conclusion

In conclusion, roof safety is an essential concern for employers and workers, as falls from height are the highest contributor to accidents in the construction industry. Suitable precautions and safety measures must be taken to ensure the safety of workers when working on roofs. This includes conducting a risk assessment, wearing appropriate clothing and equipment, using the proper point of access and equipment, using safety systems, and following established procedures for traversing and exiting the roof. By following the guidelines and best practices outlined in this guide, employers and workers can help to decrease the possibility of accidents and injuries while working on roofs and ensure a safe and productive work environment.